CNC Machining Guide for Custom Plastic Components

Every day, many Canadian engineers and designers rely on specialized partners to help them develop, improve, and manufacture innovative products. Elrex Manufacturers is one of those companies that supports product teams by providing CNC machining services for custom plastic components that contribute to technical innovation here in Ontario.

In this guide, I will introduce you to the processes, benefits, and strategies we use to quickly and confidently support you, from design to production. Among other things, I discuss how CNC plastic machining and thoughtful planning help achieve reliable results for both prototypes and production parts.

Key Takeaways

- CNC machining delivers high-precision plastic parts with tight tolerances.

- Precision plastic machining adapts to flat sheets and detailed part geometries.

- Using plastic CNC routing, CNC milling, and plastic sheet machining can help advance prototypes toward production.

- Machined plastic components support a wide range of engineered applications where accuracy, material performance, and repeatability matter.

Quick Links

What You Should Know About Precision Plastic Machining

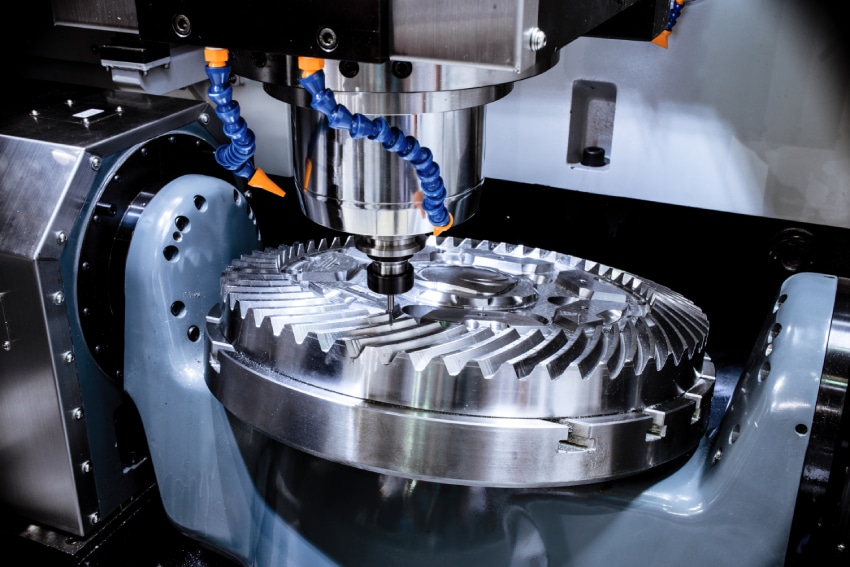

CNC machining is a cornerstone of precision plastic machining for parts that require accuracy, surface quality, and repeatability. For engineered plastic materials used in industry (such as Delrin®, PETG, Ultem®, and Nylon), CNC converts digital designs into high‑quality components typically without dedicated tooling and often with shorter lead times than mould tooling. As part of a comprehensive plastic CNC machining strategy, this approach supports prototype validation and final part manufacturing with consistent results.

High-precision plastic parts begin with robust CAM programming, which translates your CAD model into machine tool movements. From there, cutting tools interact with stock material to remove chips and shape features like holes, slots, and contours with high precision. The overall workflow supports a broad range of materials and finish requirements, making it ideal for both functional components and production-ready parts.

Clean Edge Quality and Burr Control

A key attribute of precision plastic machining is clean edge quality. CNC machines are capable of producing smooth surfaces and tightly controlled edges through optimized cutting speeds, feeds, and toolpaths. Plastics behave differently than metals under cutting forces. Without proper parameters, plastics can melt, smear, or delaminate, especially near fine features.

Effective burr control is another hallmark of professional CNC work. Burrs can interfere with assembly, cause sealing issues, or compromise functional performance. By selecting the right tooling and chip evacuation strategies, we ensure machined plastic parts maintain sharp, burr‑free edges, even on intricate features. This control also reduces the need for secondary finishing, improving lead times and production efficiency.

Plastic CNC Routing for Complex Part Shapes

For parts with flat profiles, large outlines, or open contours, plastic CNC routing delivers precise cutting with excellent surface quality. Whether working with sheet plastics or block stock, CNC routers excel at machining shapes that would be difficult with traditional milling alone. Routers can handle sizable flat areas and deeper cut requirements without sacrificing accuracy.

Plastic CNC routing is especially useful when you need to combine features such as through‑holes, pockets, and machined surface details in sheet forms. It is also commonly used for sign components, large panels, and structural features where maintaining flatness and dimensional stability are essential.

Cut Paths for Flat and Formed Parts

Cutting strategies influence final part quality. CNC routers use advanced toolpaths to maintain consistent engagement with the material and distribute cutting forces evenly. This helps reduce deflection, chatter, and surface irregularities, critical factors in high-precision plastic parts. Whether the requirement is square corners, large radii, or compound contours, careful toolpath planning drives accuracy.

For formed parts that later undergo bending or assembly, routing can pre‑machine tabs and features that aid fixture alignment. Combined with secondary machining steps, these routed components feed directly into your prototype or final assembly workflow.

Using Plastic CNC Machining for Prototyping

Plastic CNC machining plays an important role in part prototyping and early design validation. Whether starting from a flat sheet or a solid block, materials like HDPE, UHMW, ABS, acrylic, and other engineering plastics are ideal for producing test pieces, form studies, or functional mockups. Compared to moulding or casting, machining plastic stock allows teams to evaluate geometry and assembly interactions at a lower initial cost.

Short lead times and design flexibility make CNC machining a go‑to method for rapid prototyping. Machined components closely match final-part materials, helping you confirm mechanical performance, fit, and durability under load, impact, or environmental conditions.

CNC Machining for Design Validation and Functional Testing

Once a prototype is machined from stock material, it can undergo functional testing to verify that performance meets expectations. You can assess fit and alignment within assemblies, evaluate tolerance stacks, and confirm that mating parts function correctly.

This rapid CNC prototyping step helps identify surface design issues early—before committing to full production—reducing the risk of costly changes down the line. Prototypes produced from solid blocks can replicate more complex or thicker part geometries, supporting functional validation in even the most demanding applications.

Functional prototypes also make it easier to collect meaningful feedback early. When you are sharing design options with clients or supporting regulatory reviews in medical or aerospace environments, CNC-machined prototypes produced in final materials and with production-aligned processes can help build confidence before moving into full production.

Three‑Axis CNC Machining for Custom Plastic Designs

Standard three-axis machining is powerful, and for many custom plastic components, it is the most practical way to achieve precision, repeatability, and clean finishes. While certain geometries can benefit from additional axes, a wide range of complex designs can still be produced accurately through careful part orientation, robust fixturing, and multiple setups when required. This approach allows features to be machined from different faces while maintaining tight tolerances and consistent part quality.

Where designs include angled features, contoured surfaces, or hard-to-reach details, we plan the process around setup strategy and access. We sequence operations logically, use reliable locating methods, and apply machining strategies that protect surface finish and dimensional accuracy. The result is a controlled path from prototype to production for custom plastic components, including parts with demanding fit requirements and integrated mounting or alignment features.

Part Geometry and Tolerance Strategies

Effective tolerance strategies start with design intent. Critical dimensions should be defined where they matter most—interfaces, fastener locations, sealing surfaces, or areas carrying loads. Elrex Manufacturers’ CNC programmers can then prioritize these features through tool selection and sequencing.

For plastic parts, understanding material behaviour under machining forces informs tolerance expectations. Plastics can exhibit slight thermal expansion or springback effects that metals do not. Experienced machinists compensate by adjusting feeds, speeds, and path strategies, ensuring plastic part tolerances remain within design specifications.

Material selection also plays a role. Some high‑performance plastics like Ultem® or PEEK require specific cutter geometries and speeds to maintain surface finish and dimensional control. CNC programmers at Elrex Manufacturers incorporate these best practices into every job.

Machined Plastic Components for Canadian Manufacturers

Across Canada, manufacturers in telecom, medical devices, defence, and industrial markets rely on machined plastic components for both prototypes and short‑run production. If you need repeatable quality with documented material identification, I recommend CNC machining as your best bet, especially for regulated industries.

For example, telecom equipment often includes custom housings and fixtures that must hold connectors or fibre optics with precise alignment. Machined plastic parts provide the rigidity and accuracy required for these applications.

Common Applications

- Telecom: Brackets, panels, mounting interfaces, and spacers used in racks or modules.

- Medical Devices: Biocompatible housings, probe holders, ergonomic frames, and functional prototypes for clinical evaluation.

- Defence & Aerospace: Lightweight structural parts, instrument bezels, and precision mounting elements that meet demanding specification standards.

By using CNC machining, companies gain parts that align with downstream processes such as assembly, sealing, or electromechanical integration. Local machining also reduces lead times and simplifies logistics, a significant advantage for Canadian firms managing tight schedules and supply chains.

Request a CNC Plastic Machining Quote From Elrex Manufacturers

If you’re moving from design to production, you need a machining partner who understands both precision and plastic behaviour. That’s what we focus on at Elrex.

As a custom plastic manufacturer, we offer ISO‑aligned processes and plastic CNC services designed to give you consistent, high-quality results, whether you’re building a one-off prototype or a short-run production batch.

Elrex’s precision plastic machining services in Ottawa support product developers who need:

- CNC plastic cutting with burr‑free edges and consistent surface finishes

- Three-axis CNC machining capabilities for accurate features and repeatable results.

- Reliable plastic sheet machining and routing for large and flat components

- Functional prototyping parts that inform design decisions and validate assemblies

- Local support across Ontario and broader Canadian markets

Our team works closely with you to balance design requirements, material selection, and part tolerances, all within a production plan that meets your schedule.

Accelerate your development and production timelines with expert machining and local support by contacting us to discuss your project or request a quote. Let us help you create precision plastic parts to support your product development goals, regardless of your industry.

About Michael Lambersky

Michael Lambersky is the President of Elrex Manufacturers Inc, delivering high-quality, Canadian-made custom plastic manufacturing solutions. With over 15 years of experience in manufacturing he brings a strong focus on innovation, operational efficiency, and customer-driven solutions.